PRODUCT

Maximizing customer satisfaction and strengthening internal R & DWe will be a company to pursue.

PRODUCT

PRODUCT

Trading ITEM

Trading ITEM

MONITORING SYSTEM

MONITORING SYSTEM

MONITORING SYSTEM

HMI Monitoring Introduction (Gas Detector Monitoring System)

· Purpose And Construction Status

· Definition And Advantages / Disadvantages Of HMI Tools

· The System Default Configuration

· The Default System Configuration Detailed Description

· System Data Flow Configuration

· Monitoring Screen And Function Explanation

· Definition And Advantages / Disadvantages Of HMI Tools

· The System Default Configuration

· The Default System Configuration Detailed Description

· System Data Flow Configuration

· Monitoring Screen And Function Explanation

System Outline

This system enables to monitor and control various measuring and controlling facilities by integrating

them in semiconductor and LCD manufacturing processes.

Multiple communication connections are possible and it can monitor and control the on-site situation

connected with PLC or equipments.

them in semiconductor and LCD manufacturing processes.

Multiple communication connections are possible and it can monitor and control the on-site situation

connected with PLC or equipments.

Advantages

- Stabilization of communication, Data processing speed and UI.

- Modularization of various functions.

- Foreign/local PLC Communication drivers supported.

- With various alarms, Immediate Recognition of on-site situation and Rapid Response are possible.

- By reporting various Control/Trend Data to upper system, it’s easy to determine the cause of a Problem.

- With the Zoom Function of Trend Data, Specific details of small Trend change are confirmed.

- Modularization of various functions.

- Foreign/local PLC Communication drivers supported.

- With various alarms, Immediate Recognition of on-site situation and Rapid Response are possible.

- By reporting various Control/Trend Data to upper system, it’s easy to determine the cause of a Problem.

- With the Zoom Function of Trend Data, Specific details of small Trend change are confirmed.

System Composition Status

- Developing and operating the Gas Leak Monitoring System for the semiconductor and LCD manufacturing processes.

- Monitoring of various measuring facilities and Connection with alert services.

(Light/Emergency/SMS Delivery System)

- Unrestricted web client monitoring.

- Mobile Monitoring.

- Dual Monitoring System is available for 24-hour operation.

(automatic switching in the event of some system failure)

- Monitoring of various measuring facilities and Connection with alert services.

(Light/Emergency/SMS Delivery System)

- Unrestricted web client monitoring.

- Mobile Monitoring.

- Dual Monitoring System is available for 24-hour operation.

(automatic switching in the event of some system failure)

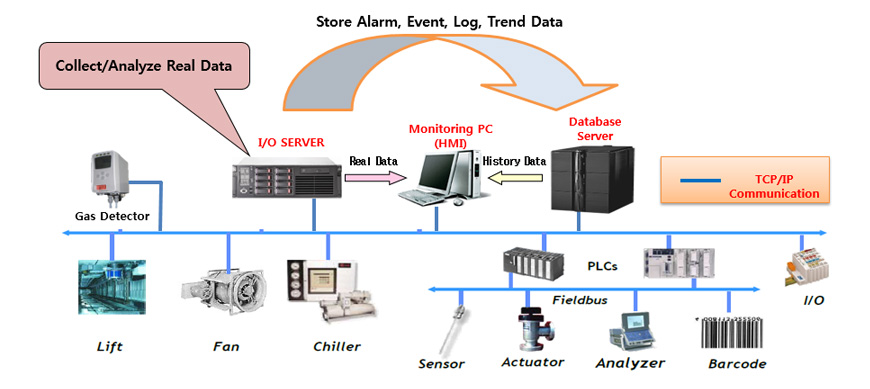

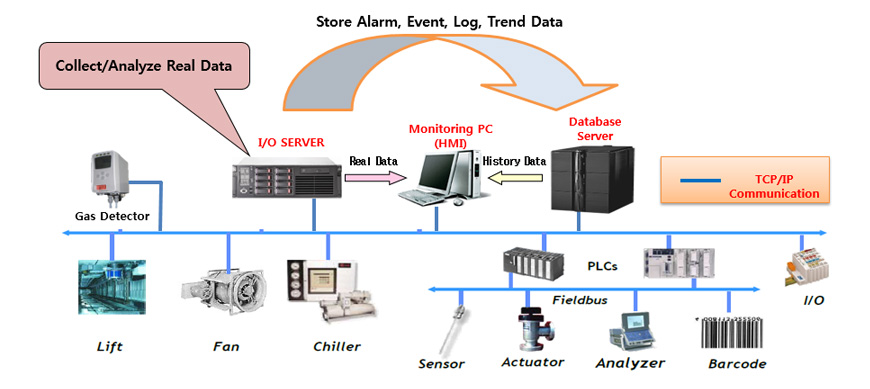

System Basic Configuration Instruction

- TCP/IP Communication among PLC, Various facilities and Upper System.

- CMS(Central Monitoring System) Composition

· I/O SERVER : Data Collecting and Communication.(Foreign/Local PLC communication Drivers supported)

· DB SERVER : Store History DATA.

· Monitoring PC : Operated by User. (Monitoring and Control)

- User receives Real Data from I/O Server and History data from DB server.

(If Detector Quantity is less than 250points, Monitoring System Construction is possible with 1 PC.)

- CMS(Central Monitoring System) Composition

· I/O SERVER : Data Collecting and Communication.(Foreign/Local PLC communication Drivers supported)

· DB SERVER : Store History DATA.

· Monitoring PC : Operated by User. (Monitoring and Control)

- User receives Real Data from I/O Server and History data from DB server.

(If Detector Quantity is less than 250points, Monitoring System Construction is possible with 1 PC.)